Glossary of Screen Printing Terminology

Screen Printing is a printing method where ink is driven through a stencil with a squeegee– but you probably knew that. It’s all the other jargon that can feel like the screen printing business has its own language. Here’s a comprehensive list of terms, inks and equipment to help you understand what’s going on and get going with your next print project.

Terms

Terms

All the terms you might hear thrown around when researching screen printing.

Bit Map– an image created on a visual display unit where each pixel corresponds to one to more bits in memory, the number of bits per pixel determine the number of available colors. Bitmapped graphics is often referred to as raster graphics.

Bleeding– This occurs when an ink migrates outside the area it’s meant to be in. This can occur with 2 different colors printing closely as well.

Blend– Printing two or more inks at the same time to create a gradient like an effect.

Butt Registration– When the edges of 2 different printed colors come edge to edge but do not overlap.

Burning a Screen– Exposing a prepared screen to a very bright light to harden the emulsion. Wherever the light hits the emulsion, the emulsion itself hardens. Wherever the film blocked the light out, the emulsion remains somewhat soft and is washed out of the screen. What is left on the screen is the stencil.

Color Separation– When you send a screen printer a full-color image, color separators then figure out how to break down your image so that it can be printed. This is done using bit mapping and halftones.

Coverage– The quality or amount of ink that is laid down onto a shirt when printed through the screen. Also referred to as the opacity.

CMYK– Cyan, Magenta, Yellow and Key or Black. These 4 colors, when combined, can make almost any color. This video discusses the difference between CMYK, RGB and color matching used during our screen printing process:

DPI– This stands for “dots per inch”. It is a measure of printing resolution that indicates the number of individual dots a printer can produce in a linear one-inch space

Dye Migration– This occurs when you are printing on a polyester shirt. On these shirts, the dye sits on top of the fibers in little beads of vapor. When you print, the ink goes over that dye, when your shirt is put through the dryer those beads of vapor turn into gas and fuse to the inks. This can change the color of the inks based on the color of the shirt they are printed on. Example: white ink printed on top of a red shirt might come out with a pink tint.

Flashing– the process of printing the same ink color twice on a garment. It is most often used when printing a lighter color ink on a darker color material.

Flood– The act of spreading ink over the screen and then pushing the ink through.

Gap Registration-The alignment of artwork in which a gap exists between one color and another.

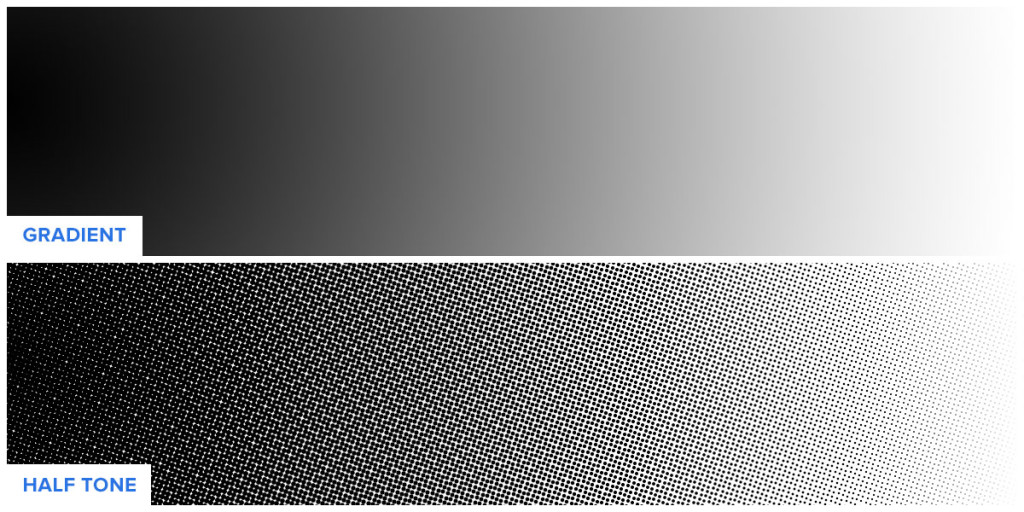

Halftone– Halftone is the process that creates images through the use of dots, varying either in size or in spacing. The dots are so small, to the eye they blend together to create varying shades of a color.

Ink Well– The side of the screen where the ink is placed.

Knocked Out– Omitted portions of artwork in a design that prevent other colors from over printing. See Stencil.

LPI (Lines Per Inch)- a measurement of printing resolution. A line consists of halftones that are built by physical ink dots during printing to create different tones. LPI is a measure of how close together the lines in a halftone grid are.

Mesh– This is the material which is stretched over the silk screen frame itself. Different screens have different mesh counts. The lower the number, the more ink it allows in.

Mesh Count– This is the number that refers to the size of the openings in between the filaments of thread in the mesh. Higher numbers have small openings while lower numbers have larger openings. Using a higher mesh count will have a softer feel.

Over Printing– Printing one color on top of another color.

PMS Color– PMS stands for Pantone Matching System. It is a method of consistently matching colors developed by Pantone. A general standard for the screen-printing industry is the Solid Coated book.

Registration– The alignment of one color of artwork with another. Multicolor prints require the different colors of the artwork to line up correctly with each other.

Run Off– This refers to prints that appear to extend past the boundaries of the shirt or other printed apparel. These prints work better on some apparel rather than others (we suggest your run off design does not go over any thick seams or pockets as this will interrupt the continuous look special to this type of print).

Spot color– A spot color is any color generated by an ink that is printed using a single run.

Separations / Seps– Once your art is created, each color must be printed on a clear film called separations. These will be used to burn the images for each color into the screen.

Serigraphy– a technical term for screen printing.

Trap– a technique in three color printing where the bottom color “bleeds” out from under the ink that will be printed on top of it. This limits the gaps that can be caused from misregistration.

Vector Graphic– In simplest terms, vector graphics is created using lines and points instead of pixels. This means that it can be stretched or shrunk to nearly any size without compromising the integrity of the art.

Under Base– Printing a layer of white ink before any other colors when creating on darker garments. This allows the colors to stay true and maintain opacity over the dark fabric.

Viscosity– Commonly referred to as the “thickness” or “thinness” of an ink.

Equipment

These are the tools and equipment used during the screen printing process

This is our automatic press operating in our Cleveland, Ohio location

Automatic Press– A screen printing press that operates by using electric motors and hydraulics. An automatic screen printing press has a much higher production rate than a manual press and will typically produce a higher quality print result.

Film/Film Positive– This is the clear piece of “plastic” with your artwork printed onto it in all black.

Printer / Platen– This is a square metal or wooden frame with a screen made of mesh material very tightly stretched over it.

Pictured: The metal frame is the platen, the screen in the inner part that is stretched and holds the artwork

Silk Screen / Mesh– The screen or artwork used to print a particular color.

Squeegee– This is a tool with a flat rubber blade on one side used to pull ink evenly across the screen.

Pictured: Squeegee & Scraper used for screen printing

Stencil– This is the portion of the screen that is not covered and allows ink to go through the screen to be printed onto the surface underneath.

The yellow part of these screens is the part of the screen that the ink will be pushed through and leave a design on your apparel

Inks

These are different types of inks that can be used during screen printing and their benefits and characteristics

Cured Ink– Ink that has been through the oven at about 330 degrees Fahrenheit. Curing is the actual chemical process of the ink drying and bonding to the shirt fabric.

Discharge Inks– Discharge inks literally “discharge” the color out of a tee so that the original color of the tee is “bleached” out. It also produces a soft feel as opposed to plastisol, which can give you a rough feeling imprint. Discharge inks only work on 100% cotton apparel.

Discharge Ink

Metallic Inks– A plastisol ink base containing metallic particles.

Metallic Ink

Plastisol ink– These inks sit on top of threads instead of soaking into them and are not water soluble. They are best for printing opaque graphics onto garments.

Plastisol Ink

Specialty Inks– Specialty inks refer to pretty much anything other than plastisols. These can sometimes include discharge and water-based inks but, is more commonly used when referring to Foil transfers, glow-in-the-dark, puff ink and other unique types of ink.

UV Inks– A types of ink that, when exposed to UV light, will harden or cure.

Water-Based Inks– Ink made up of water that dyes a garment directly, becoming a part of the fabric, rather than laying on top of a shirt

If you have questions about screen printing or what we can do here, contact us! We’ve been screen printing since 1999 and have been able to work with some fantastic artists and we’d love to work with you.