What to Expect With Over the Zipper Screen Printing

Screen printing is a lot like painting with a roller. On a flat wall, the paint will go on evenly and smooth. When the roller hits a bump in the wall, it skips a space and there is a break in the color, a little gap that the paint doesn’t hit. Fleece hoodies are mostly smooth unless you hit a zipper or pocket. Luckily, we’re experts at Jakprints and we have the know how to work around these limitations.

Apparel with non-traditional print areas is extremely popular right now. But, this type of printing often comes with its own challenges, like how to get your design to look good while printing over seams and zippers. This can be tricky but not impossible and the final products are always worth the effort. We sat down with Jeff Wisenberg, head of Apparel Production here at Jakprints, to get some tips and information about the process of printing over zippers.

What to Avoid

Some designs work better than others, here are some elements to avoid if you’re planning an over the zipper print.

Anything symmetrical – “Typically anything symmetrical, like text, won’t work because the garment will get shifted slightly while it is being printed,” says Jeff. Getting the text to line up cleanly is very hard to do on fabrics because of their fluid nature.

Heavy, Solid Designs – These designs will cause ink build up. Ink build up occurs when ink gets stuck in grooves because you’re printing on fibers that are not completely flat like paper. To reduce this, we use halftones or simulations so that there is some space between the dots to decrease the amount of build up.

Lightweight Hoodies -For printed zip-up hoodies, we have pallets with gutters that the zipper can rest in. These pallets are built for heavyweight sweatshirts that are much thicker than these lightweight hoodies. Because of this, their zippers sit lower in the gutter creating an uneven surface for printing.

Uncovered Zippers – We are only able to screen print over covered zippers. If we print over an uncovered zipper, the ink will dry and harden over the zipper and prevent it from functioning:

Pictured is a lightweight hoodie with an uncovered zipper, while still great for screen printing, not great for over the zipper prints

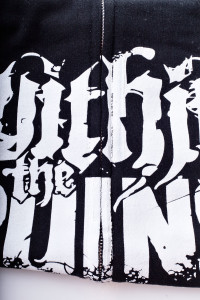

Designs that Work

Distressed graphics or graphics with a vintage feel work really well for over the zipper printing. Designs that naturally lend to looking a little broken and imperfect will mask any misregistration or gaps that are common when printing over an uneven surface.

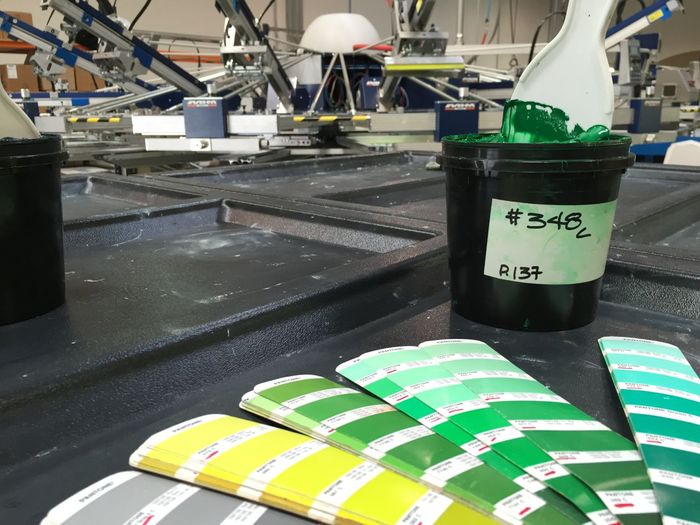

Inks

Inks play a huge part in what your final product will look like. These are the inks we use for our screen printing and the differences between them.

Discharge and water based inks are great when you have a solid image but don’t want it to feel too thick. Rather than having a bunch of plastic based inks sitting on top of the shirt, these inks are discharged into the fabric of the garment.

Water based inks are a special type of ink that soaks into the fabric rather than sitting on top like traditional plastisol. The benefit of these inks is that you are left with a super soft, vintage print. You won’t even be able to feel it on the garment. Typically, we can only use water based inks on designs that us less than 4-5 colors and do not use halftones or are highly detailed. This is because of the fluid and vintage look of the inks.

Discharge Ink is a type of water-based ink that also soaks into the fabric. The only difference is that there is a discharge or “bleaching” agent mixed into the ink that removes the dye already in the fabric. This type of ink is made for darker colored garments that produce bright colored prints on darker garments with a soft to the touch feel.

Plastisol Inks sit on top of the shirt and are extremely opaque. When you think of a screen printed shirt, this is probably the type of ink you picture. These inks are not water based and can last a very long time. They have a plastic feel to them and become shiny when layered.

Trial and Error

We’ve made some mistakes so you don’t have too. We have a pretty great system going now and we’re always improving our techniques!

One of the biggest and most expensive mistakes Screen Printers make is over or under flashing fleece. Flashing is the process of curing the same color ink to a garment twice so that a lighter color ink will show up on a darker material.

Over flashing will burn the fleece and cause registration issues. This causes the fabric to shrink meaning the rest of the screens won’t match up.

To solve this, we use a fast-flashing base white on these garments. This two-second flashing base white allows us to print over zippers, pockets and seams with little error.

This part of the process is important to your final product because it creates a more uniform and consistent print when all of the screens match up. Not over flashing will also help your print last longer and have a better, purer color.

Color Separation Solutions

Color separation is a huge part of screen printing and our team at Jakprints is the best around. For more information about it, check out this interview with LT Magnotto from our Color Seps team about screen printing. Keeping color seps in mind while you’re designing will help you better understand how your final product will look.

Typically, you would want to choose the smallest dot size your screens and presses are capable of printing.

“It is important to train those creating the separations to keep a keen eye on the type of material on which each order is to be printed,” says Jeff.

Switching to larger LPI (lines per inch) is an easy way to ensure those screens clear with a single hit. The larger the dot, the lower the mesh you can run. While a typical mesh would be a 225 or 300 for T-shirts, 110, 160 and 200 are better suited for printing on even the most challenging fleece apparel.

For a more technical description about how we make screen printed hoodies with pockets and zippers, check out this blog Jeff wrote a few years ago for Print Magazine. It will give you details about our automatic screen printer and more tips for how to get the cleanest print.

The key to getting a final product you can be proud of is talking to us about what you want. We can answer any specific questions you have about your design and how to get your ideas onto apparel. Contact us with any questions you have, we can’t wait to get started on your next apparel project.